Does anyone else do this? Probably not. The material is very hard to source, the commercial product is not expensive, and most good quality flylines have welded loops already. So why do I do it? I have no idea, but here’s how…

You’re going to need some braided material. I have some Gudebrod. I don’t think they make it any more. It’s too heavy for all my flylines, but it works ok for #8+

It came with a super tricky little hook tool, but I prefer a stout darning needle.

I cut about 24cm. That gives me 8cm of double, and 8cm to attach the flyline.

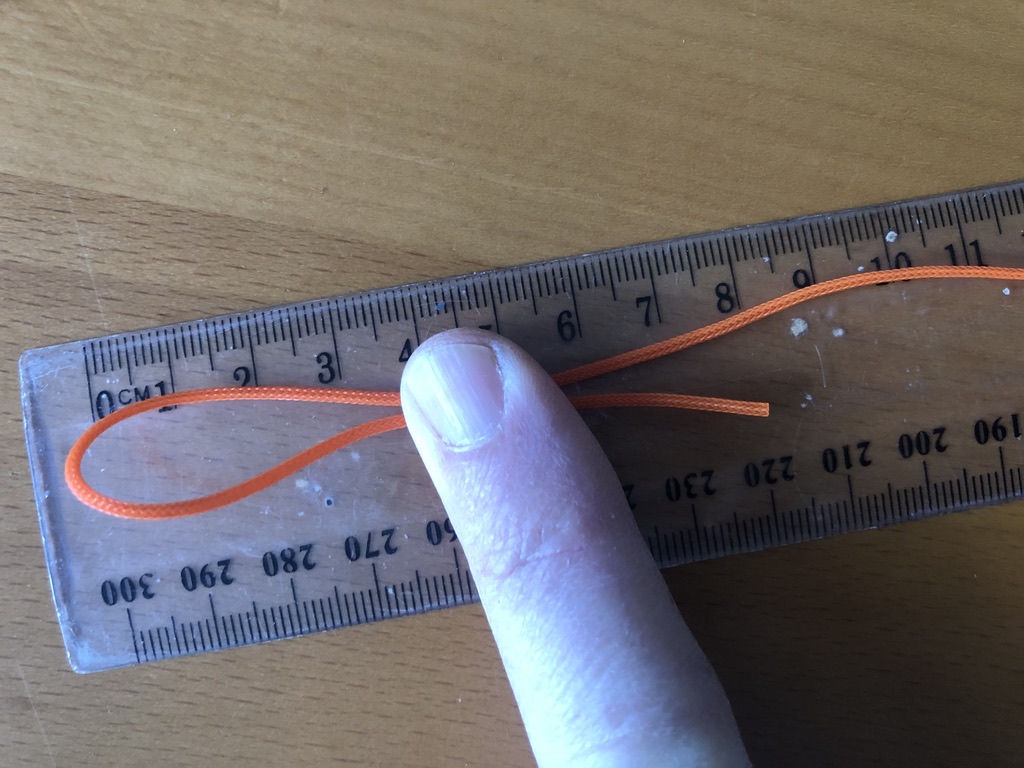

Fold the line to create an 8cm double.

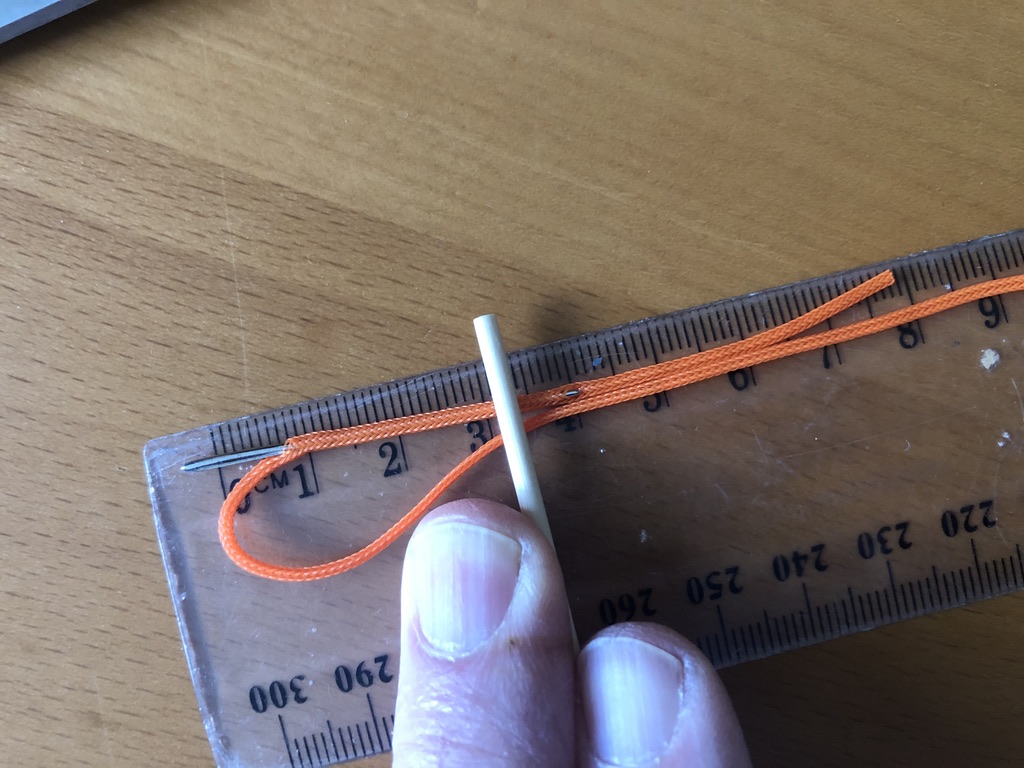

Insert the needle near the loop and exit about half way/4cm. along the short end.

Thread the tip of the long end through your needle and draw it through with the needle. So now your short end is about 4cm and the long one about 12 cm.

Now, repeat with the short end, drawing it though the long one, and exiting after about 4cm.

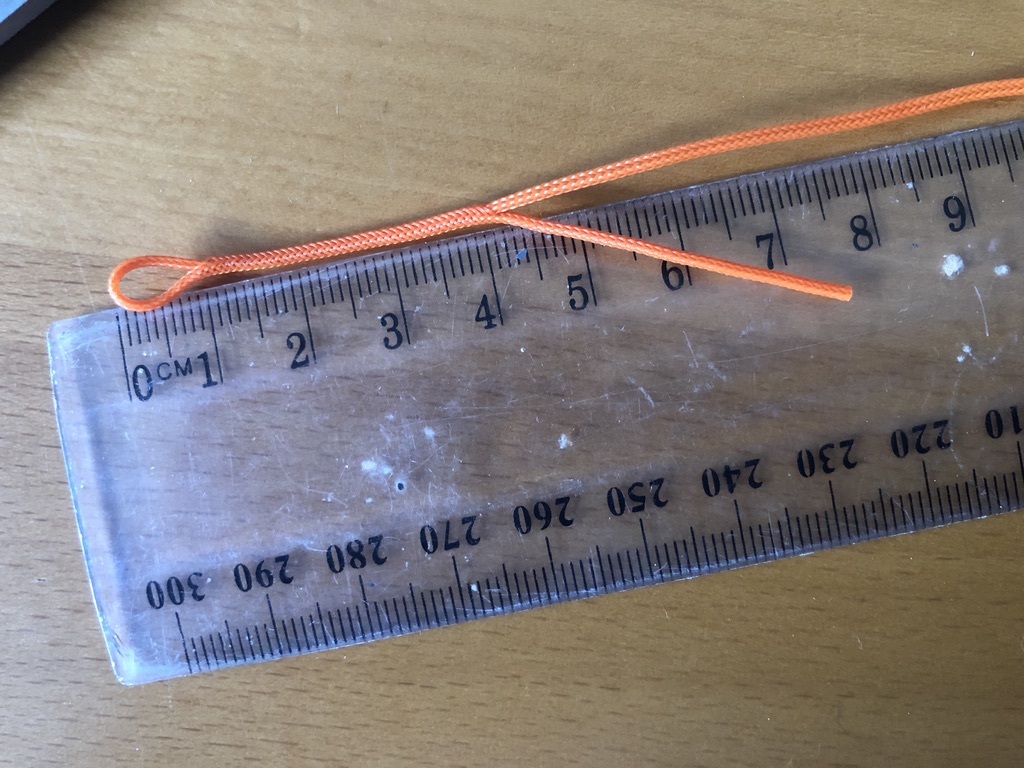

If you get the lengths right, the short end will draw up inside the long one, with no cutting required. The long end is now 8cm or so, and ready for you to feed in your flyline.

I like to add a little whip finish with some rod building silk (mine’s also Gudebrod!), and varnish with some UV resin. I also soak a little bit of super glue into the area where the flyline meets the enclosed braid end.

Neat as a pin, eh?